Oxygen Absorber Australia – A Truely Innovative Australian Success Story

Innovative Uses and Benefits of the patented OxySorbTM Oxygen Absorbers

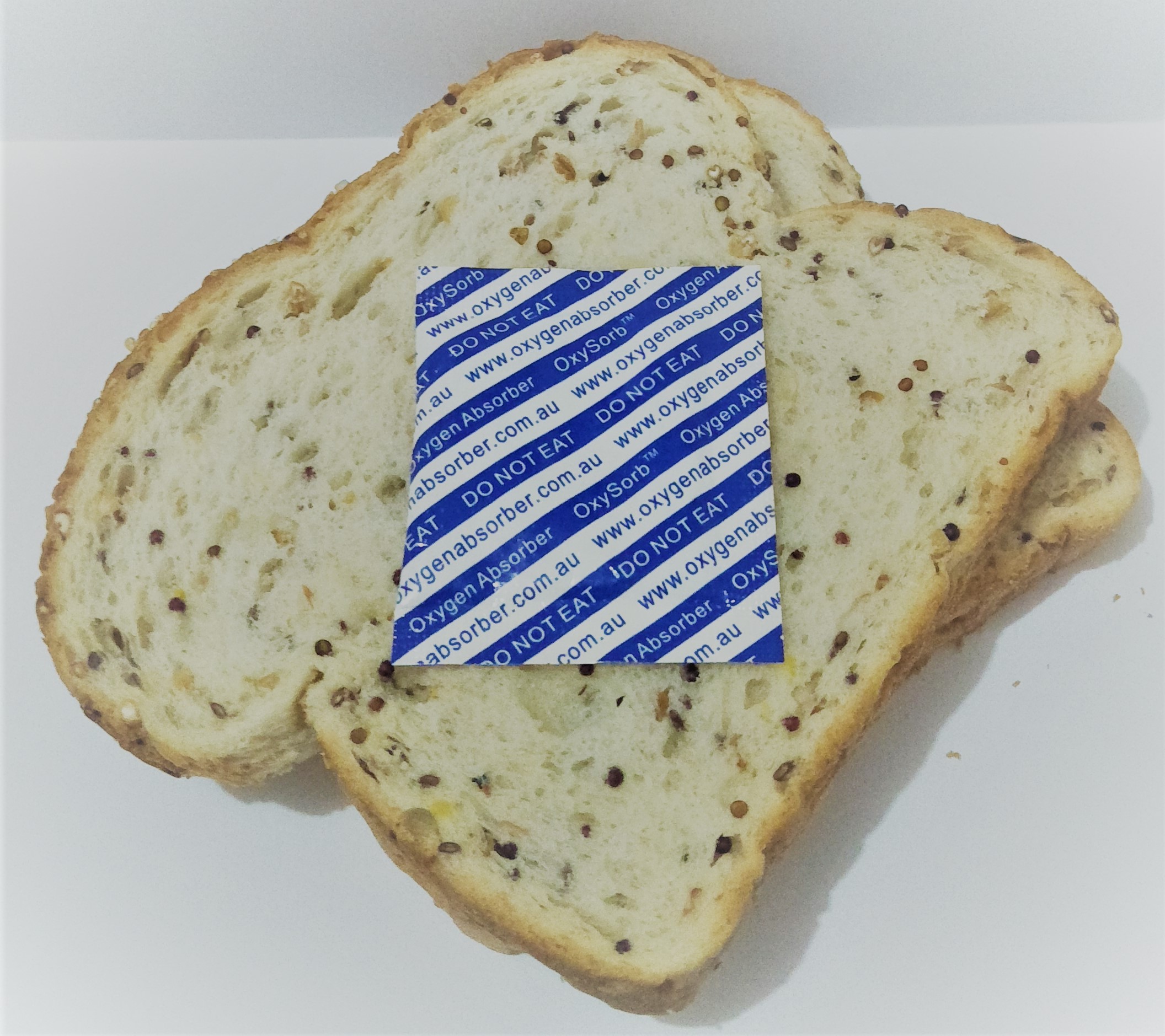

Melbourne, Victoria Feb 3, 2022 (Issuewire.com) – OxySorbTM Oxygen absorbers are highly useful little satchels that are added to enclosed packaging to modify the atmosphere to eliminate oxygen in the package. Without oxygen most food spoilage mould, ‘fungi’ cannot grow.

OxySorbTM Oxygen absorbers depend on a chemical reaction to work and contain iron particles (ferrous carbonate) that oxidize when they react with the moisture and oxygen molecules in the air and rust.

Once this reaction is complete and the oxygen levels are reduced to 0.1%, the saturated or unsaturated oxygen absorbers lie dormant.

Then, the iron comes in contact with rising oxygen levels and the chemical reaction starts again until all (or most) of the oxygen is removed from the air.

There are many types of OxySorbTM oxygen absorbers available to cover a wide array of applications, and you can shop online for them on the Oxygen Absorber Australia website (https://www.oxygenabsorber.com.au).

Uses of OxySorbTM Oxygen Absorbers

OxySorbTM Oxygen absorbers, as their name suggests, absorb oxygen packaged products, prohibiting the growth of fungi and aerobic bacteria. They can reduce the oxygen level in the surrounding environment to approximately 0.01%. They are commonly utilized to extend the shelf-life of a vast array of different foods, including:

- Beef Jerky

- Bread and other grains

- Coffee

- Fresh fruit and vegetables

- Nuts

These absorbers are not only useful in the food industry but the pharmaceutical industry and other non-food industries as well.

For example, they can help improve the shelf-life of various pharmaceutical products, and they can help to preserve important historical documents, art, and other precious artifacts that can be harmed by the presence of oxygen.

Benefits of OxySorbTM oxygen absorbers

Oxygen absorbers have a wide range of benefits in the food industry, pharmaceutical industry, and more besides. These benefits include, but aren’t limited to:

- Less waste

- By increasing the shelf life of food, oxygen absorbers help to prevent food waste (OxySorbTM are 97% can be used as a soil conditioning agent.

- OxySorbTM is patented in Australia [IP AustraliaPatent Number; 2017101028]

- OxySorbTM Oxygen absorbers can also improve the shelf life of expensive pharmaceutical products, leading to less being wasted

- Safer, healthier products

- It can be very harmful to people to consume foods that have had growth of pathogens, fungi, and bacteria caused by oxygen in beverages, food, and pharmaceutical products

- Oxygen absorbers can help reduce or eliminate the need for added food preservatives, which is great for those interested in natural foods

- Non-intrusive

- OxySorbTM Oxygen absorbers are small in size, so they don’t take up valuable packing space

- OxySorbTM Oxygen absorbers do not alter the taste, color, or texture of the goods

- Inexpensive

- This safe and simple solution for long-term storage saves money every day by keeping the product in good condition for a longer

You can find out more information and obtain high-quality oxygen absorbers by visiting https://www.oxygenabsorber.com.au/.

Extensive Research and Development

People often ask me, what is the difference between an oxygen absorber and an oxygen scavenger?

With respect to small devices that are added to food, and pharmaceutical products, oxygen absorbers, oxygen scavengers are the same thing, just different names for the same thing.

Oxygen scavengers or oxygen absorbers are added to packaging with food or pharmaceutical products, much like silica gel, and then enclosed to modify the atmosphere in the packaging (i.e. remove oxygen to leave nitrogen and carbon dioxide). This leads to improvement of product safety and shelf life extension. An extensive review has been written by Cichello 2015, with the ferrous type being most common, there are many other oxygen absorbers available to cover a wide array of applications and varying absorption efficiency and speed.

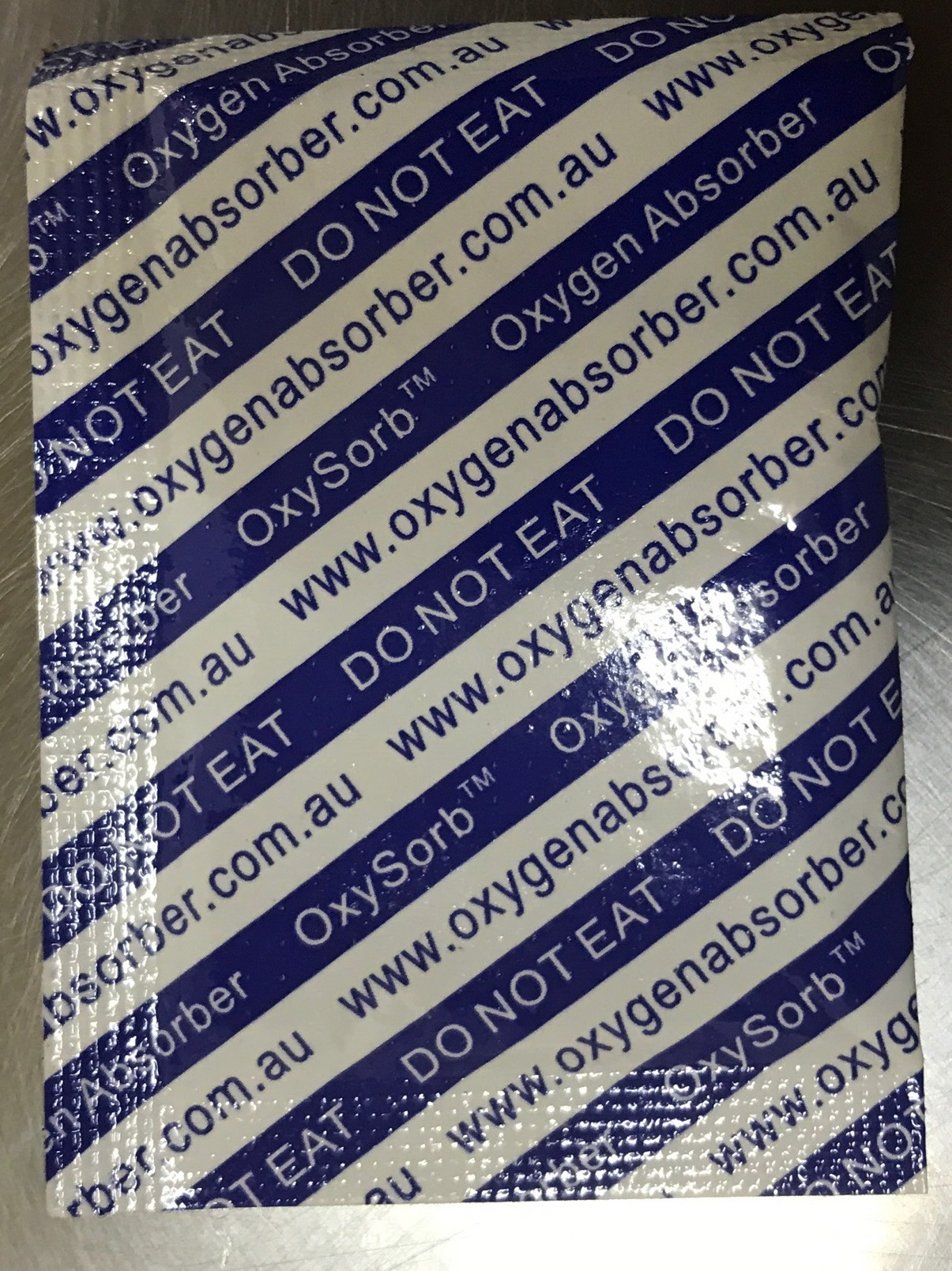

The components of an oxygen absorber vary according to intended use, but typically contain a hydrated metal carbonate i.e. iron II carbonate or calcium carbonate, with a desiccant such as activated carbon [water adsorption sites], salt as a catalyst, and some moisture. The oxygen absorber or scavenger, like silica gel desiccant, is enclosed in a porous sachet or packet typically paper or polyethylene combination but can also be embedded into packaging films and structures or polymer structures. There are some innovative patents that propose the re-use as a soil fertiliser/ conditioner.

The first patent for an oxygen scavenger used an alkaline solution of pyrogallic acid in an air-tight vessel, but also the use of ascorbic acid by the British military in food rations in the 1930s.

When an oxygen absorber is removed from the master packaging with a low oxygen transmission rate, the atmospheric moisture begins to become adsorbed onto the activated carbon and interact with the iron particles inside of the absorber sachet, and oxidizes to form iron oxide (i.e. 65% relative humidity); see figure 1 below, with salt acting as a catalyst at lower humidities, as a result, the oxygen level in the surrounding atmosphere will fall below 0.01% with 1 g of iron adsorbing 300 mL of oxygen. Non-ferrous oxygen absorbers/ scavengers exist but due to the price of other metals and also ascorbic acid, ferrous or calcium carbonate are generally used. Another substitution for ferrous carbonate, Zinc, Manganese, Boron, etc, but iron is the cheapest metal that can oxidize and thus the most used. Other nonmetal compounds including ascorbic acid can be used. A good introduction can be found here. A comprehensive review by Cichello 2015 can be found here. Also a useful Facebook page; Oxygen Absorber Australia.

Their size of oxygen-absorbing capacity can range from 20cc, the smallest, to 50cc, 100cc, 200cc, 300cc, 400cc, 500cc, 1000cc, and 2000cc is one of the largest.

The activated carbon absorbs moisture, and the salt acts as a catalyst to activate the oxidation of the ferrous carbonate to ferric oxide. Due to residual moisture added, oxygen absorbers are self-acting and commence absorption as soon as the oxygen absorber packets are exposed to oxygen (i.e. bag is opened).

The benefits of oxygen scavengers include;

– The removal of oxygen, leading to less oxidation of flavour compounds in foods i.e. retaining the fresh-roasted flavor of coffee and nuts, prevents the oxidation of spice oleoresins present in spices themselves and in seasoned foods

– Prevents oxidation of vitamins A, C, and E extends the life of pharmaceuticals

– Inhibits mold growth in bread, beef jerky, cheeses, reducing non-enzymatic browning of fruit and vegetables,

– Killing insects and weevils in a museum/ art gallery environment (oxygen deprivation)

– Oxygen scavenging technology can quickly reduce oxygen levels in sealed containers to below 0.01%.

Moreover, OxySorb oxygen absorbers are packed with an oxygen indicator.

The indicator may be comprised of methylthionine chloride (<1%) (methylene blue) [non-toxic], and Rhodamine dye (<1%); which changes from a pink colour to blue colour when exposed to oxygen and atmospheric moisture.

Typically foods with an available water content of less than 0.6 may not need an oxygen absorber if hermetically sealed and the oxygen transmission rate of the container is <1cc/m^2/24hr period at ambient conditions.

To calculate the correct sized oxygen absorber to use, you need to contact a technical specialist as there are at least if not more than 10 factors that could impact oxygen in the product and thus the shelf-life of the product.

Contrary to popular belief, OxySorb oxygen absorbers can actually be reused as a soil fertilizer. See patent below for description, this is the only one in existence globally and registered by Wholesale Group International Pty. Ltd. [IP Australia Patent Number; 2017101028]

Summary

Oxygen absorbers absorb oxygen. They can be in a powdered form added to the film, or food i.e. ascorbic acid (vitamin C) (Dave et. al. 1997). They are sometimes also called ‘Oxygen Scavengers’, ‘oxygen absorber packets’, ‘o2 absorbers’, ‘oxygen packs’, ‘oxygen removers’. Primarily, oxygen absorbers are used for food storage i.e. fresh fruit and vegetables (Charles et. al. 2003), walnuts (Jensen et. al. 2003), raw almond kernels (Mexis & Kontominas 2010)& fruit colour stabilizers (Tarr & Clingeleffer 2005), with CO2 absorbers in strawberries (Aday et. al. 2011; Kartel et. al. 2012) but also for use with pharmaceutical products and also equipment storage as well. Extensive literature reviews regarding oxygen absorbers and active packaging have been written by Miltz & Perry 2004, Han 2005, Rooney 2005, Kadoya 2012, Tian et. al. 2013, Realini & Marcos 2014 & Cichello 2015. They can be placed in high oxygen barrier containers i.e. HDPE tubs or packaging i.e. PVdC coated PET/ or Nylon. A popular choice is mylar bags which are commonly used in food storage. Mylar food storage bags are used by the military but also by those preparing for food shortage which is a normal occurrence in nature and also human civilisation due to war, famine, and pestilence.

Some common brands include OxySorb (Wholesale Group International), Ageless (Mitsubishi), which are food-grade oxygen absorbers; HACCP and USFDA compliant, and so forth. Often, oxygen absorbers are used in combination with moisture-absorbing packets such as silica gel or silica/ clay gel desiccants. They are not ‘deoxidizers’. They can be combined with ethanol emitters (Latou et. al. 2010) in sliced wheat bread preservation, gluten-free bread (Gutiérrez et. al. 2011), combined with rosemary oil extract in rainbow trout fillets (Mexis et. al. 2009), Greek cod paste (Mexis et. al. 2009), catfish steaks (Mohan et. al. 2006), chicken meat and citrus extract (Mexis et. al. 2012)and modified atmosphere packing with pork sausages (Martínez et. al. 2006), chocolate (Mexis et. al. 2010), milk powder (Thomsen et. al. 2005), with Kerry et. al. 2006reviewing applications in meat, and Tian et. al. 2013 lipid oxidation.

We also supply the oxygen absorber dispensers as well.

If you need an MSDS or other information feel free to contact us directly; [email protected]

Thanks for reading!

More information

OxySorbTM Oxygen Absorber Australia is the industry leader in the supply of food technology and packaging product solutions, including the implementation of oxygen absorbers and an assortment of other absorbers in food products to extend shelf-life. The company provides services all over Australia, including Melbourne, Sydney, Canberra, Adelaide, Brisbane, and Perth.

To find out more, head over to the official website which contains additional resources.

Media Contact

Simon Angelo Cichello

0412359026

Level 1, Level 1, 530 Little Collins

Source :Melbourne Detective

This article was originally published by IssueWire. Read the original article here.