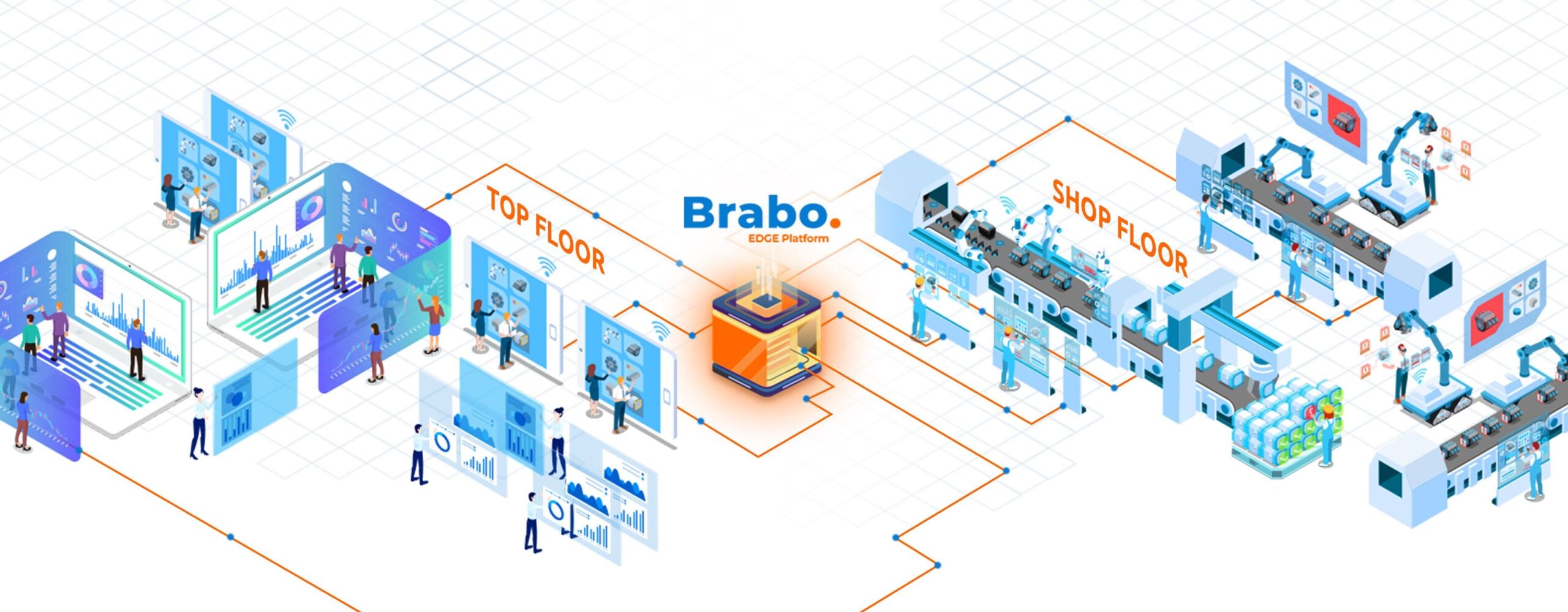

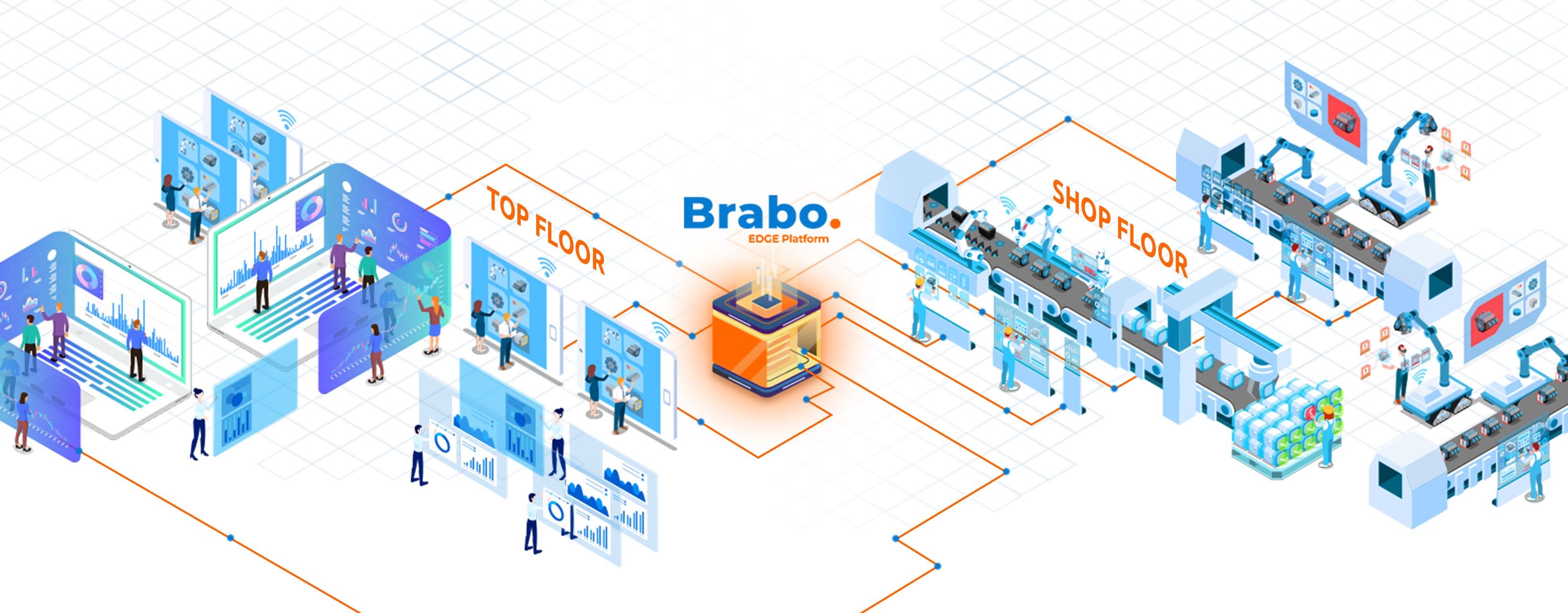

How is Brabo a Game Changer? We deliver our Edge platform and solutions.

Noida, Uttar Pradesh Mar 15, 2022 (Issuewire.com) – The manufacturing industry has been faced with numerous challenges. Some of these issues may include the lack of sufficient capital expenditure for smaller firms, lack of IT skillsets, security of data, ability to scale the operations, and many more. Due to these challenges, some of the manufacturers may take a step back while taking up digital transformation in their business. To help resolve the complexities of Industry 4.0 led operations, Solulever, a Dutch technology start-up has launched its unique Edge platform, named Brabo. Brabo, a state-of-the-art Industry 4.0 platform provides OT-IT connectivity at a large scale for most manufacturers of all sizes. It eliminates the various integration challenges, especially the OT connectivity issues that are mostly underestimated alongside providing careful orchestration to avoid data gaps. Through this manufacturing connectivity and intelligence platform, OT integration is given prioritization over IOT to leverage existing investments and the technology landscape is simplified. Brabo is a hybrid platform that is cloud-based and edge-based as the data storage and computes choice is based on use case fitment. Being edge-based, it stores and processes all the site-level data locally. By being cloud-based, it dynamically chooses data workloads that flow to the cloud for cross plant/ cross product for benchmarking, application development, and reporting. The hybrid architecture of the product collects real-time data from the equipment and tools installed at the manufacturing unit which is spontaneously mashed up with the operational data to enable contextualized intelligence. It enables real-time contextualization of machine data over business parameters such as SKUs, batch number, material number, customer ID, etc. This way the business operations become smarter in nature as the number of anomalies are reduced and the process becomes more efficient. The Edge platform is a game changer as it enables the teams to incrementally build new applications and analytics at no additional costs. It utilizes open-source communities for plugging new analytics tools and visualizations which suit different use cases of each unique customer. It offers scalable containerized edge-based microservices organized for hyper integration, scalability, and to deliver plant-level lightweight applications. The key value proposition of the platform that places it above most of its competitors includes it being open source, based on a hybrid architecture, having the ability to provide microservices and real-time contextualization. The alternatives of this platform being offered in the market may have some of these value propositions, but it would be highly unlikely to have all of them in just a single platform. OT- IT is important to utilize the existing investments in control later to yield a better ROI from the entire shop floor. Only through these optimized OT-IT integrations, the costs can drastically be reduced by a whopping 30%. This is due to the reason that Brabo takes up analytics first approach towards application design, making deployment a must for digital operation programs. Alongside, it makes use of distributed analytical application blocks rather than siloed thick MES/ MOM layer. It realized that for customer programs to succeed, and Edge platform must make use of a business case-driven approach, which it follows religiously. Brabo also enables quick time to value realization for different business cases which usually ranges between 9 to 12 months. This makes it easy to adopt the solution for most of the customers, making it easier for them to move in the direction of smart manufacturing.

Media Contact

Nilanjan

07005226918

Solulever, 1st floor Plot no. 7 IHDP Business Park,, Sector 127, Noida, Uttar Pradesh 201301

Source :Solulever

This article was originally published by IssueWire. Read the original article here.