How to Find Wear and Tear in the Mobile Stone Crushers?

How to Find Wear and Tear in the Mobile Stone Crushers?

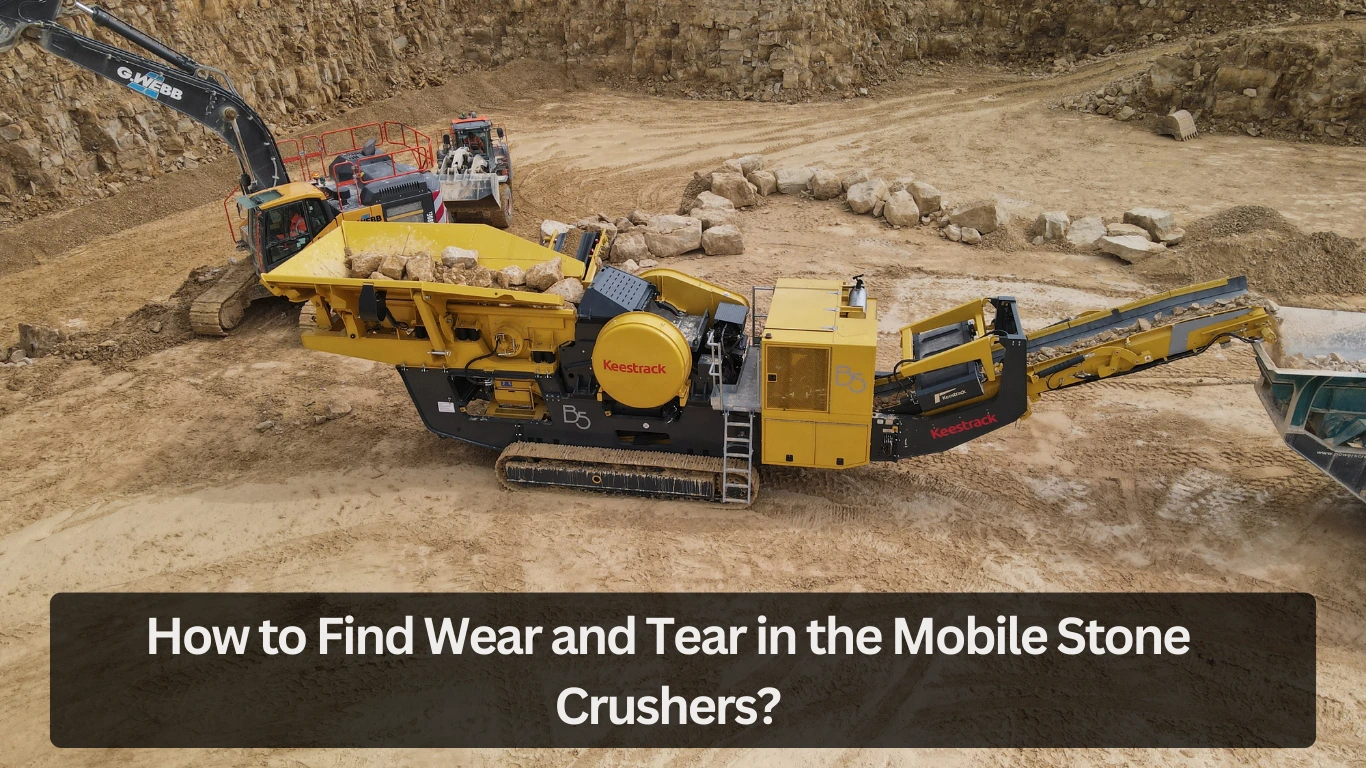

In aggregate machines such as mobile stone crushers in India, wear and tear are quite inevitable. This is because of the huge amount of friction and pressure that is placed on the machine while grinding the hard as well as soft materials. Over time, the machine can stop working or show some kind of damage that can affect productivity and efficiency.

In case you do not know how to find the wear and tear in the machine, you are at the right spot as we are going to discuss a few things here. So, let us get started.

Why you should spot and fix the wear immediately?

There are several benefits of spotting the wear and fixing them promptly. Some of them have been discussed below:

- Enhanced lifespan of the components: When you fix any error or wear and tear in the components after consulting the best crusher manufacturers in India, they will easily last longer.

- Decreased costs and time for maintenance: Less maintenance will be needed when the machine is in the right condition. It will help you save your money as well as time.

- Increased productivity and reduced downtime: When you do not have to spend much time on maintenance or no requirement for replacing components so often, you can spend more time on producing more aggregate.

How to locate wear and tear in the mobile stone crusher?

Before an adverse season starts, it is always a good idea to check all the machines including the mobile crusher to see if it is working correctly or need any replacement or repair. All these will help you maximize the machine and production during the crushing season.

Now, the question is – how can you find any issue? Below, we have highlighted some of the ways to do so. Have a look:

- Check the components regularly

Many people consider it as overkill but this is essential. However, you are advised to allocate a trusted and experienced technician to keep a check on every component. This will help you keep the operations of the crusher or the plant on full steam. Since damaged parts can easily be eliminated if you maintain the machine regularly, it will turn out to be a pocket-friendly decision as you can avoid expensive repairs and replacements. For instance, if you replace the mainframe liner promptly, it will cost you less. In case you do not do it, the damaged component will not bring extra expenses but affect the production.

- Always follow the specifications and instructions of the manufacturer

When you buy a mobile stone crushing machine, you will find a manual given by the crusher manufacturer in India. When you check it, you will find some maintenance tips. This is something you will need to do to locate the wear signs. Since the machine comes with a manual wherein you will get detailed information about the ways to examine, maintain, replace, etc. By checking out the manual, you will also know the methods to make the most out of each component.

- Understand the common signs and areas of damage

Do you know the areas in a mobile stone crusher where most wear and damage happen? Well! There is no fixed spot where a wear can appear. It means damage can take place anywhere on the machine. However, some significant spots are there that must be checked regularly as they face the most pressure while crushing or grinding the materials. These include mainframe liners, manganese liners, screens, conveyors, bearings, feeders, and so on. Therefore, you must assign an expert who should check all these components daily to locate any issue in the initial stage only.

- Understand the design limitations of the crusher

Whether you have purchased a cone mobile stone crusher in India or any other type, you should understand its design and limitations. By knowing the same, you will get an idea about the parts that can easily get damaged. In addition to this, you will also know the capacity of each component to avoid excessive pressure while operating them. In simple terms, when you know the designs and limitations, you will get an idea about the ideal operational conditions of the stone-crushing machine.

- Always replace parts with the high-quality ones

In case you find any damaged parts in the crusher, you are advised to replace them promptly. However, it is recommended to opt for the high-quality parts only. You must get the parts that can easily be maintained and scaled as per the applications. In addition to this, you should always get the parts that can also meet the specific needs of your operational site and the project type.

Summing it up!

Do not know which part is damaged or when to replace it? If yes, then you can get in touch with Etrack Crushers. Here, you will find an expert team who will assist and guide you to decide better on the mobile stone crushers, gravel screens, and other industrial machines. For more details, you can also visit the official website for detailed information.