“Performance meets sustainability”: Klüber Lubrication, a brand of Freudenberg at Windergy 2022

Specialty lubricants for higher turbine availability and lower maintenance costs!

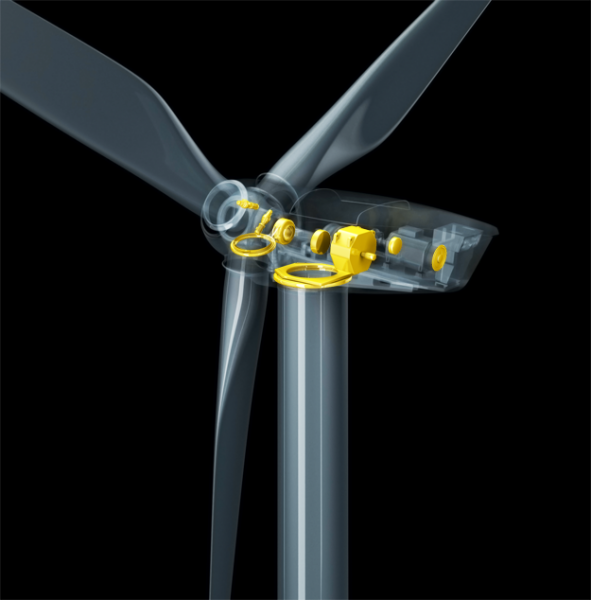

New Delhi, 12 May 2022 – The installation of ever larger wind power stations for higher capacities means operators constantly face new challenges in terms of operational reliability and maintenance. A major topic in this context is the reliable lubrication of wind turbines and their components. Under the motto of “Performance meets Sustainability“, at Windergy 2022 in New Delhi, Klüber Lubrication presented a comprehensive portfolio of services and their efforts towards a sustainable future, designed to meet the specific needs of the wind power industry,

“Our products and solutions for Wind Turbine lubrication have been developed to increase component life, reduce service intervals, downtime and minimize operational complexity,” comments Joseph Robert, Head of Global Business Teams at Klüber Lubrication India Pvt Ltd. “While our headquarters are at Germany, we have a state of the art manufacturing facility as well as a full fledged R&D center at Mysore, India, to cater to the unique needs of our customers in India and the Asia Pacific region.”

“Our products and solutions for Wind Turbine lubrication have been developed to increase component life, reduce service intervals, downtime and minimize operational complexity,” comments Joseph Robert, Head of Global Business Teams at Klüber Lubrication India Pvt Ltd. “While our headquarters are at Germany, we have a state of the art manufacturing facility as well as a full fledged R&D center at Mysore, India, to cater to the unique needs of our customers in India and the Asia Pacific region.”

Klüberplex BEM 41-141 was developed for maximum performance in all roller bearing applications of the wind turbine, namely – the generator bearing, blade bearing, main bearing and the yaw bearing. This product has been used for decades by most major OEMs. When compared with other multi-application greases available in the market, Klüberplex BEM 41-141 has proved to be the most suitable grease for all bearing applications in a wind turbine lubrication. This has been validated by relevant test rigs, decades of field experience and approvals by most major global OEM’s.

“Having a single grease that can be used across a range of application requirements has clear benefits. It reduces complexity by streamlining logistics, minimizes the potential for cross contamination with other greases and delivers a uniformly high lubrication film thickness for all the applications in a Wind turbine “ says Joseph Robert.

Clean components generate production increases

With the limited availability of high performance greases in the past, many wind turbine operators encounter the phenomenon of grease deposits being build up in the generator bearings. This is because of hardened thickener adhesion to the bearing surface due to oil separation from the grease at higher temperatures, which leads to vibrations, bearing damage and at times even turbine shutdowns due to temperature spikes. Kluber Lubrication has developed a new cleaning grease, Klübersynth BZ 68-400, which is proven to reduce temperature shutdowns to almost zero. Operators can remove deposits and clean bearings while the turbine is in full operation mode. The grease comes in easy-to-use packages and can be applied manually with a grease pump or via an automatic lubrication system.

Geared up for success

Another product that has proven highly effective in numerous wind power plants is the synthetic gear oil Klübersynth GEM 4-320 N. This oil is particularly suited to the specific requirements of the wind power sector due to its high scuffing and micropitting strength as well as its degree of wear protection. It is also particularly resistant to ageing and oxidation and shows a good viscosity-temperature behaviour. Furthermore, the synthetic gear oil Klübersynth GEM 4-320 N has excellent antifoaming characteristics. All of these properties combine to increase the life of the gearbox and ensure hassle free turbine operation.

Preventive maintenance through lubricant analysis

The experts from Klüber Lubrication also present a wide range of services in the field of speciality lubrication, lubricant condition analysis is also one of the most sought after service provided in India, at their test facility in Mysore.

Machine availability is a key factor for operators of wind turbines, lubricant analysis can provide information that helps to detect any potential issues with the lubricant itself and more importantly with the component. This knowledge when received in time, immensly reduces the failure risk of expensive components and thereby optimizes machine availability.

Contributing to a Sustainable Future

By 2045, Kluber Lurbication and its parent company, Freudenberg group aims to become a climate-neutral company. The 2025 target is to achieve a 25 percent reduction in specific CO2 emissions per million euros of sales when compared with its emissions of 2020. With this aim in mind, the company is pursuing a strategy based on energy-saving, electrification, the purchase and generation of green power and the offsetting of CO2 emissions. One example is their Power Purchase Agreement in collaboration with Volkswagen and power producer RWE, covering the supply of 172 MW of solar electricity from Tramm-Göthen, home to Germany’s largest photovoltaic park.

Apart from Klüber Lubrication’s own sustainability goals, they help their customers to be more sustainable. The company has developed a new biodegradable grease for the yaw gear and sliding bearings of wind turbines – Klüberbio LG 39-701 N. The high-viscosity base oil of Klüberbio LG 39-701 N comes from 100 % renewable resources and is biodegradable. This means there is a considerably lower impact on the environment in the event of leak, or contact with seawater or land.

Klueber Lubrication’s efforts towards Sustainability have been recognized by being awarded a Gold medal by EcoVadis Sustainability rating. Founded in 2007, EcoVadis is the world’s largest and most trusted provider of business sustainability ratings, creating a global network of more than 90,000+ rated companies. The emphasis on sustanability continues at Klueber Lubrication India’s manufacturing plant in Mysore. The latest proof is the solar panels on the plant’s roof. “ The photovoltaic system installed at our Mysore plant will reduce smog-causing NOx emissions by 3.5 tons, SOx emissions, which could result in acid rains by 3.2 tons. This will also decrease asthma-causing particulates by 0.2 tons. In addition, the project will reduce CO₂ emissions by roughly 1,110 tons, which is equivalent to having more than 88,000 trees“, says Joseph Robert.